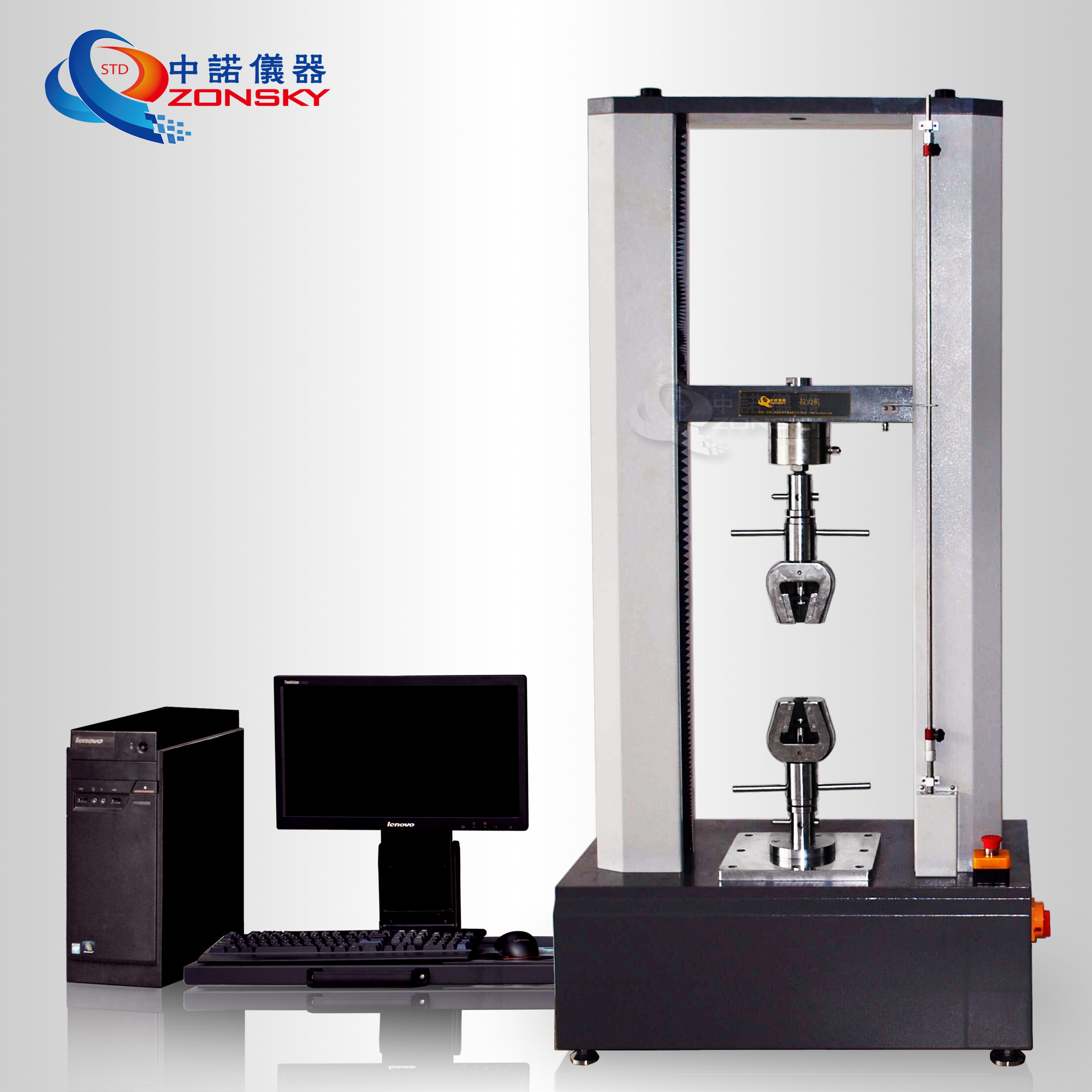

The universal material test device is also called a hydraulic universal material test instrument. It is a well-designed by Zonsky and cooperated with rigorous quality management. It is widely used and can implement stretching and compression tests. It can test various materials such as: plastic products (cloth, tube, board) rubber (plate, tube), tape, tire industry, textile, acrylic, FRP, EVA, PE and shoe dumbbells or semi -finished products. It can test its tensile strength, elongation rate, tearing, peeling, and strength.

Comply with GB/T2611-2007 "General Requirements for Testing Machines" and "Electronic Universal Testing Machines" GB/T16491-1996 standards.

Comply with GB/T2611-2007 "General Requirements for Testing Machines" and "Electronic Universal Testing Machines" GB/T16491-1996 standards.

Universal material test machine test control system

It is specially designed for microcomputer electronic universal material test machines, microcomputer hydraulic universal material test machines, and microcomputer pressure machine design. It can perform tensile, compression, bending, cutting, tearing, and stripping test. It uses PC and interface boards for data collection, preservation, processing, and print test results. It can calculate parameters such as the maximum, yielding, average divestickness, maximum deformation, yield point, and elastic modulus. It can perform curve processing, multi-sensor support, graphic image interface, flexible data processing, MS-ACCESS 2003 database support, making the system function stronger.

It supports nine types of text: Chinese simplified Chinese, traditional Chinese, English, Spanish, Russian, Japanese, French, German, Portuguese, and arbitrarily switch. The database field of the test data shows the automatic translation of the selected text, so that the data is convenient to browse in the local text, and basically meet the use of the test machine in the world;

It supports 3 types: SI international standard units, KG-CM units, LB-Inch-made units, 6 commonly used units: N-MM-MPA, KN-MMPA, GF-CM-KGF/CM2, KGF- CM-KGF/CM2, LB-Inch-KPSI, KP-Inch-KPSI, unit switching is convenient. It meets the use of standards in different regions.

It uses the USB2.0 communication interface with photoelectricity, which completely solves the damage of the computer serial port or circuit board serial port caused by incomparable due to the incompleteness, and achieves hot insertion of the computer and the test machine circuit.

Software uses rights level management: test staff level authority, test management authority, and test machine manufacturer authority, which takes into account the convenience and security of use.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now