The fire hose is a hose for transporting flame-retardant liquids such as high pressure water or foam. The traditional fire hose uses rubber as the inner lining and wrapped with linen weaving fabrics on the outer surface. Advanced fire hose are made of polymerization material such as polyurethane. There are metal connectors on both ends of the fire hose, which can be connected to another hose to extend the distance or connect the nozzle to increase the liquid jet pressure.

Although in general the quality of fire hose is good, we must prevent poor quality varieties from flowing into the market, causing hidden dangers of fires hazard. The fire hose also has a certain validity period. Once beyond the validity period, a new fire hose is required. How long is the validity period of the fire hose? Does the applicable period of fire hose clearly specify?

Although in general the quality of fire hose is good, we must prevent poor quality varieties from flowing into the market, causing hidden dangers of fires hazard. The fire hose also has a certain validity period. Once beyond the validity period, a new fire hose is required. How long is the validity period of the fire hose? Does the applicable period of fire hose clearly specify?

Our country China does not have clear relevant regulations.

(1) Determining whether the fire hose meets the fire extinguishing requirements, we can judge from whether it is damaged from the surface of the appearance, whether the diameter and length are matched with the fire hydrant, and whether the inner layer of materials are aging. " Specifically, you can compare the standard GB 6246-2011 "Fire hose"(DIN 14521-1987 / NF S61-820-1/IN1-2010 / NF S61-820-2/IN1-2010).

(2) It is recommended to replace the hose that has been used for 12 years. In daily management, it can test some fire hose every six months to test the pressure and time. China has not stipulated the replacement period, and it should be replaced in a timely manner according to the actual situation of the hose products.

And according to relevant national regulations, the fire hose must be replaced or going to the fire maintenance unit for maintenance once, and it is detected at least once a year, because the fire hose needs to withstand high water pressure during use. If the time is too long, the inner wall adhesion will be occurred. General rubber fire hose: one year of shelf life; PVC fire hose: two years; polyurethane fire hose: two years. Of course, this is just a reference value. It depends on the quality and use of the product. Finally, remind you that the temperature difference between the storage environment is small, the 15 degrees Celsius is the best, and the no corrosive object gas, etc., so that the storage time is longer.

Fire hose test instrument configuration:

No. | Test items | Product model | Product name | Unit | Standard terms |

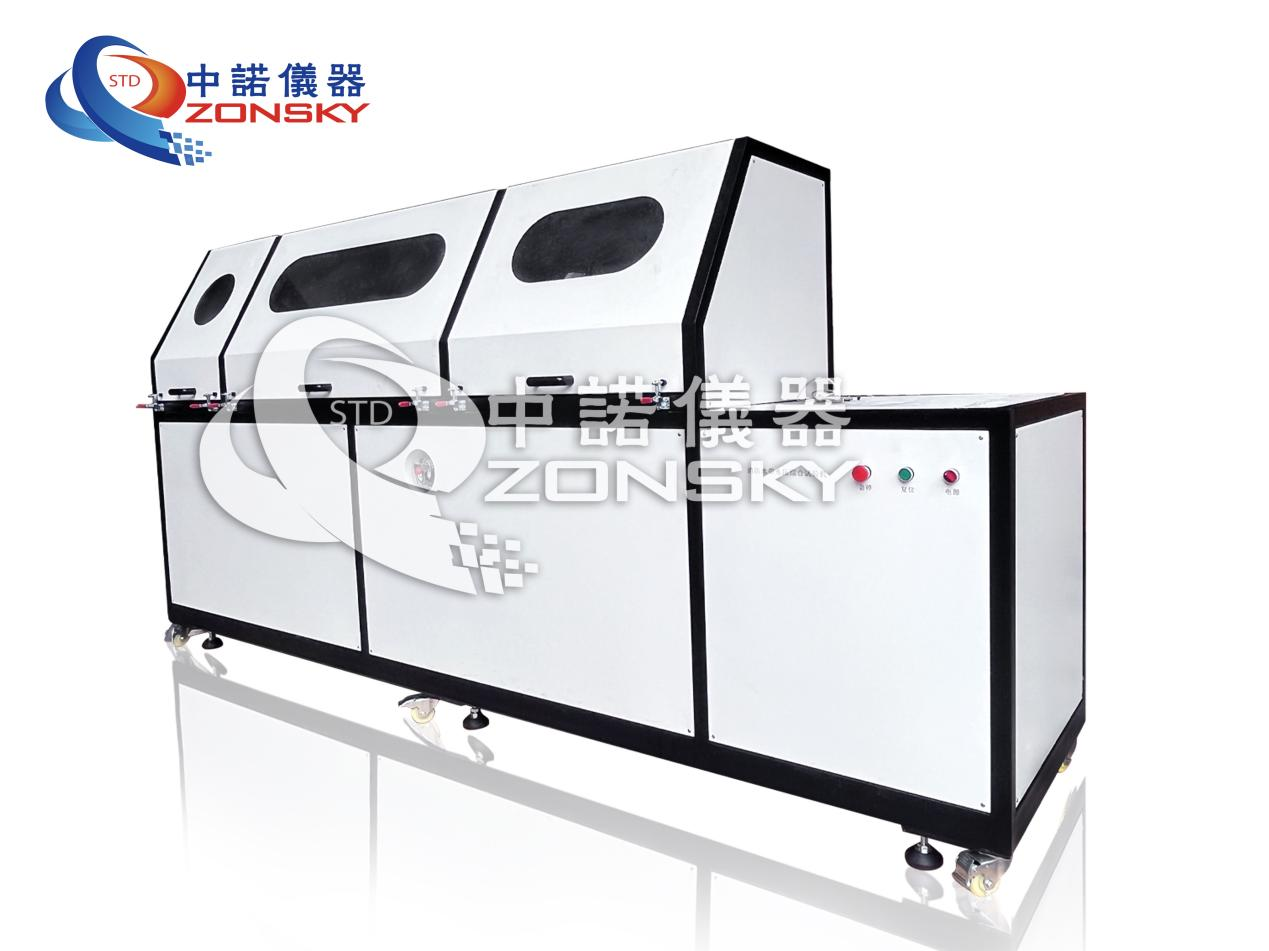

4.1 | Water pressure test and blasting test | ZY6501-PC | Hydraulic comprehensive testing apparatus of fire hose | 1 set | 5.4 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.2 | Extension rate, expansion rate and twist direction test | ZY6501-02 | Fire hose extension and twisting test apparatus | 1 set | 5.7 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.3 | Bending test | ZY6501-01 | Fire hose bending test apparatus | 1 set | 5.8 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.4 | Adhesion test | ZY6010H-500K | Fire hose physical mechanics performance test apparatus | 1 set | 5.9 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.5 | Performance test of low-temperature-resistance | ZY6046-2000L | Programming constant temperature and humidity test apparatus | 1 set | 5.10 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.6 | Attachment strength test of lining (or outer layer) | ZY6010H-500K | Fire hose physical mechanics performance test apparatus | 1 set | 5.11.1 of 5.10 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.7 | Line (or outer layer) extension and pull-apart strength test | ZY6010B-500K | Fire hose physical mechanics performance test apparatus | 1 set | 5.11.2 of 5.10 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.8 | Line heat air aging test | ZY6011B | Programming thermal aging test apparatus | 1 set | 5.11.3 of 5.11 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.9 | Wear resistance test | ZY6501-03 | Fire Hose Wear-resistant Test Apparatus | 1 set | 5.12 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

4.10 | Fire hose and fire coupling connection performance | ZY6501-PC | Hydraulic comprehensive testing apparatus of fire hose | 1 set | 5.13 in GB/T6246 (Related reference: DIN 14521-1987 NF S61-820-1/IN1-2010 NF S61-820-2/IN1-2010) |

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now