ISO7165,Fire Extinguishers,Hydraulic test on Fire Extinguishers,Burst Tests on Fire Extinguishers,If you want to make hydraulic test and blasting test of portable water-based fire extinguishers, dry powder fire extinguishers, carbon dioxide fire extinguishers, and clean gas fire extinguishers, or deformation test and burst test of simple fire extinguishers that can be moved freely and the filling volume of fire extinguishing agent is less than 1000 mL, our test apparatus ZY6503-PC can help you!

ISO7165,Fire Extinguishers,Hydraulic test on Fire Extinguishers,Burst Tests on Fire Extinguishers,If you want to make hydraulic test and blasting test of portable water-based fire extinguishers, dry powder fire extinguishers, carbon dioxide fire extinguishers, and clean gas fire extinguishers, or deformation test and burst test of simple fire extinguishers that can be moved freely and the filling volume of fire extinguishing agent is less than 1000 mL, our test apparatus ZY6503-PC can help you!

Firstly, it complies with the standard requirements of GB4351.1-2005 "Portable Fire Extinguishers — Part 1: Performance and Construction" Section 7.8.1 Hydrostatic Test and Section 7.8.2 Burst Test and GB/T4351.3-2005 "Portable fire extinguishers — Part 3: Regulations" related to hydraulic test and blasting test standards. It conforms to ISO 7165:1999 "Fire fighting — Portable fire extinguishers — Performance and construction" standard requirements. Also it meets the requirements of 6.5.2 deformation test and 6.5.3 blasting test standard of GA 86-2009 "Simplified fire extinguishers".

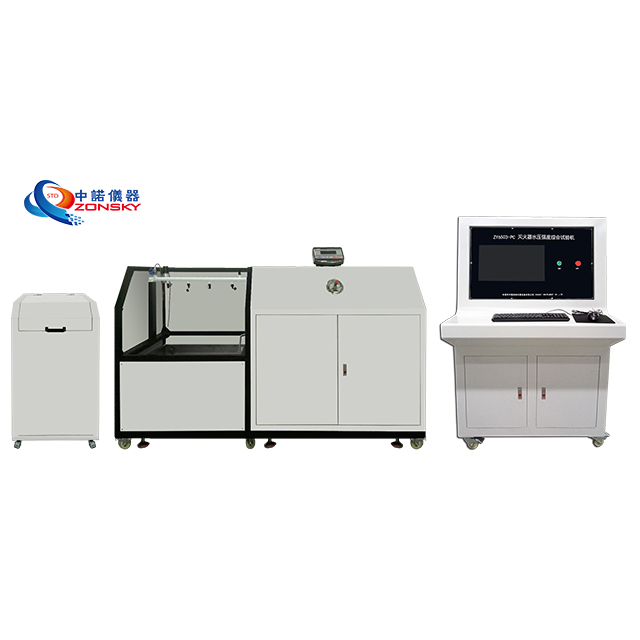

Secondly, let’s see the structure of the equipment. It is composed of hydraulic test part, blasting test part and computer operation control part. The system is automatic boost control, and it can also be operated manually. The cabinets are the visible pressure-resistant operating consoles with front and upper doors. The high-pressure system adopts double insurance precautions, that is, the pressure transmitter controls the water pressure, and the electric contact pressure gauge controls the maximum water pressure. On the one hand, if there is a failure, on the other hand, it can also ensure the safety of test personnel and equipment. The high-pressure pipeline is made of several times the pressure resistance capacity and is durable. The overall design is reasonable, and the maintenance is convenient and fast. The test pressure control is precise and high, and the error of the stabilized pressure is far better than the national standard. It's made of high-quality steel plate, the surface is treated with electrostatic baking paint, durable and practical, beautiful and generous. The test is automatically controlled by the computer, and the test data is automatically recorded throughout the process. After the test, you can click to generate an Excel report as required to achieve efficient automation. The control software adopts LabView, a special development software for precision instruments and equipment of American NI Company, with flexible interface operation, and the sensor has a calibration interface. PLC is used to implement control, and the performance is stable.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now