In the event of a fire, doors and roller shutters act as a barrier to smoke. It ensures that the other side of the door is kept as far as possible from the fire. The pressure on the fire surface of the door will change, and the pressure difference between the two sides of the door will make the smoke flow to all possible gaps. Most doors are asymmetrical, with smoke performance dependent on the side with the higher pressure. Therefore, the determination of the smoke resistance performance of the door requires a double-sided test.

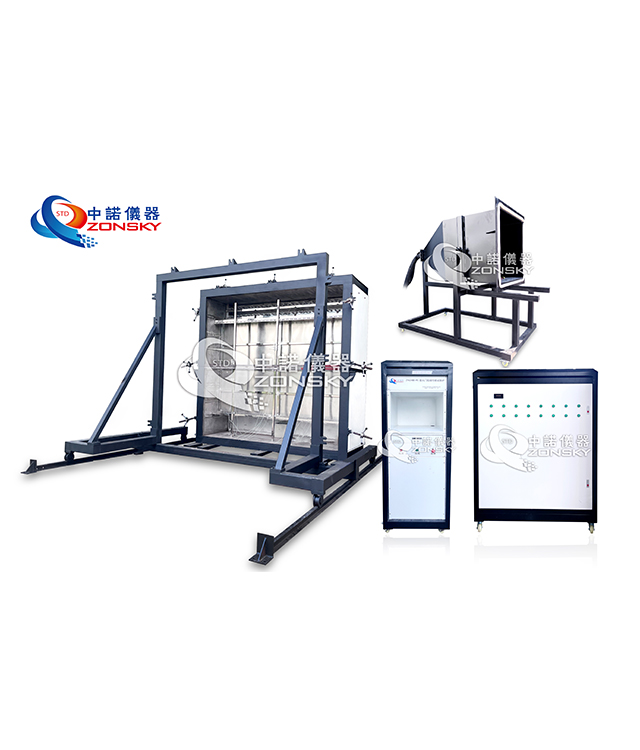

Our new design ZY6248D-PC test furnace of smoke proof performance for fire doors is suitable for fire doors of various structures that block smoke during fire. Under the specified test conditions, test the smoke leakage rate of fire doors.

It complies with the standard of ISO 5925-1:2007 "Fire Tests - Smoke-Control Door and Shutter Assemblies — Part 1: Ambient-and medium-temperature leakage tests".

It about 16-bit high-precision acquisition card to collect various data such as temperature, pressure, and flow of each channel, and generate real-time reproduction real information of combustion through computer analysis, processing and control, and directly obtain result. The whole machine adopts high-quality components to ensure high-quality and high-speed operation of the system, which is advanced.

It adopts 16-bit board + multi-channel module + microcomputer, implements PID automatic control mode, and has excellent stability, repeatability and reproducibility.

It adopts WINDOWS XP operation interface and LabView, a special development software for global precision equipment, with a fresh, beautiful and simple interface style. During the test, the measurement results are displayed in real time and the perfect curve is dynamically drawn. The data can be permanently saved, read and printed out, and the report can be printed directly. It has the characteristics of high intelligence, guided menu operation, simple and intuitive, and makes the test results more accurate;

Real-time display of the relationship between air leakage rate and time under three pressures (10pa, 25pa, 50pa);

Heating temperature control is controlled by P.I.D temperature control system.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now