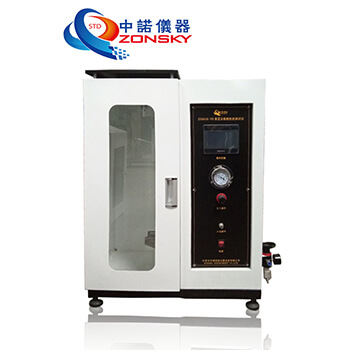

The Testing Equipment used to test the performance of flame-retardant protective clothing is the textile vertical flame-retardant test apparatus. Burn flame-retardant protective clothing samples, measure the tendency of fabrics to prevent burning and carbonization, and evaluate the flame-retardant performance of flame-retardant protective clothing. So how is the process of testing the performance of flame-retardant protective clothing carried out?

The detection method adopts the gas supply system. The propane gas is connected to the gas inlet of the instrument through the gas pipe. The pipeline system in the instrument is equipped with a gas pressure gauge, a flow regulating valve and a gas solenoid valve. When testing the performance test of flame-retardant protective clothing, the following process is carried out:

(1) Sample preparation: use a 200mm×160mm rectangular rigid sample template (with 4 holes at the four corners, and the hole spacing is consistent with the fixed needle pitch of the sample) to cut out 3 pieces of warp and weft samples. For the surface flame spread test of materials whose front and back surfaces are obviously different, 6 pairs of front and back sides should be tested separately.

(2) Humidity conditioning of the sample: Condition the humidity of the sample for at least 24 hours at a temperature of (20±2)°C and a relative humidity of (65±5)%. The test should be carried out within 2 minutes after the sample leaves the humidity-adjusted environment.

(3) Test environment: temperature 10~30 ℃, relative humidity 15%~80%, air velocity<0.2m>

(4) Surface spreading: Install the sample according to Figure 1, ignite the burner and adjust the flame length to 25mm, and adjust the burner to a horizontal position. Start the test button to start the test, and the burner will automatically leave after the flame acts on the fixed point on the surface of the sample for 10 seconds. At this time, record the spread (continued combustion) time and smoldering time of the sample, and observe and record the occurrence of holes on the sample, the debris dripping and whether the debris ignites the filter paper under the sample support device, etc.

(5) Bottom spread: Install the sample according to Figure 1, the burner is in a vertical position, ignite the burner and adjust the flame length to 40mm, and adjust the burner to be 30° from the vertical direction. Start the test button to start the test, and the burner will automatically leave after the flame acts on the fixed point on the bottom edge of the sample for 10 seconds. At this time, record the spread (continued combustion) time and smoldering time of the sample, and observe and record the occurrence of holes on the sample, the debris dripping and whether the debris ignites the filter paper under the sample support device, etc.

The equipment for testing the performance of flame-retardant protective clothing burns for 10 seconds on the surface or bottom edge of the vertically placed fabric sample through a limited flame. Record the flame spread, smoldering, dripping debris (extinguished or ignited) and holes formed by the sample, and record the spread (continued burning) time and smoldering time.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now