SHOP

Check Our Product

Bring to the table win-win survival strategies to ensure proactive domination. At the end of the day, going forward.

Description

Site-1

The Vertical Fire Resistance Furnace is used to assess the fire resistance rating for the loss of integrity and insulation of products, such as fire doors and shutter assemblies, installed in openings of vertical separating elements. ZONSKY, with 20 years of technical expertise, has developed the fire test furnace to achieve high accuracy and reliable stability. We have completed a large number of projects in China. Feel free to contact us!.

More Product Media

Site-2

Site-3

Product Demo Video

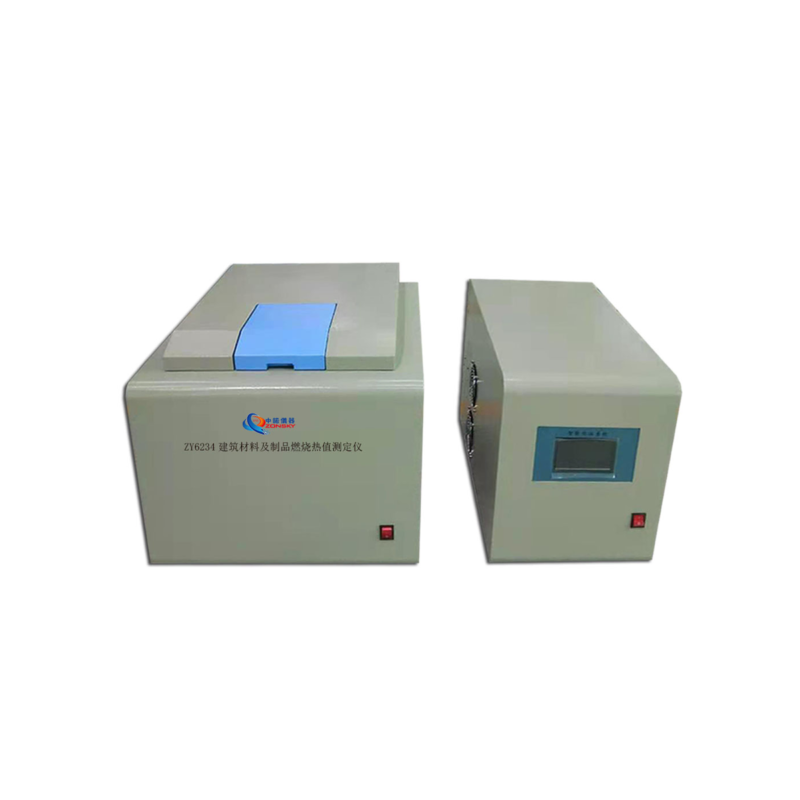

Key Components

Vertical Combustion Furnace: Testing Method Overview

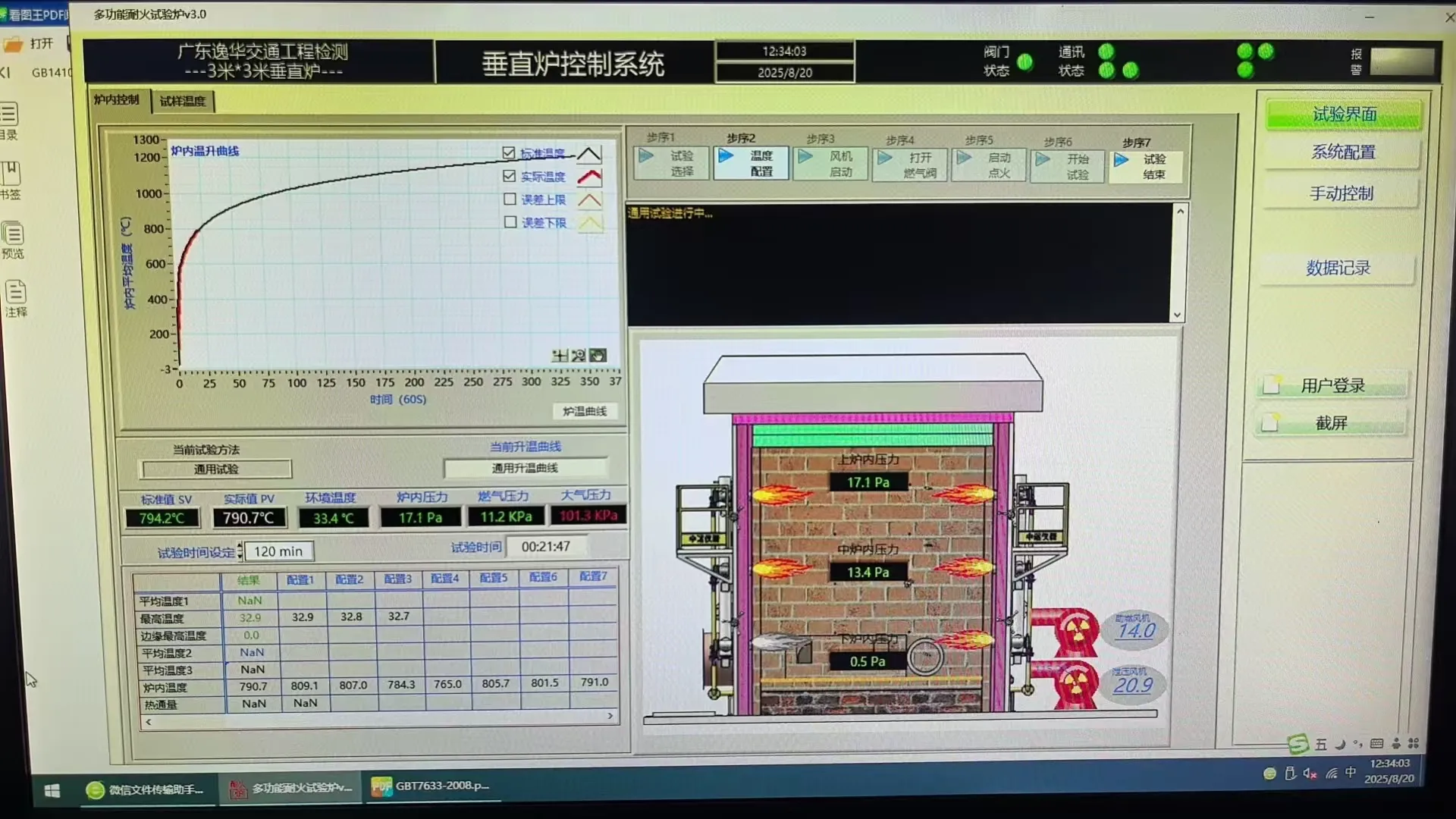

ISO834-1 Standard heating curve-1

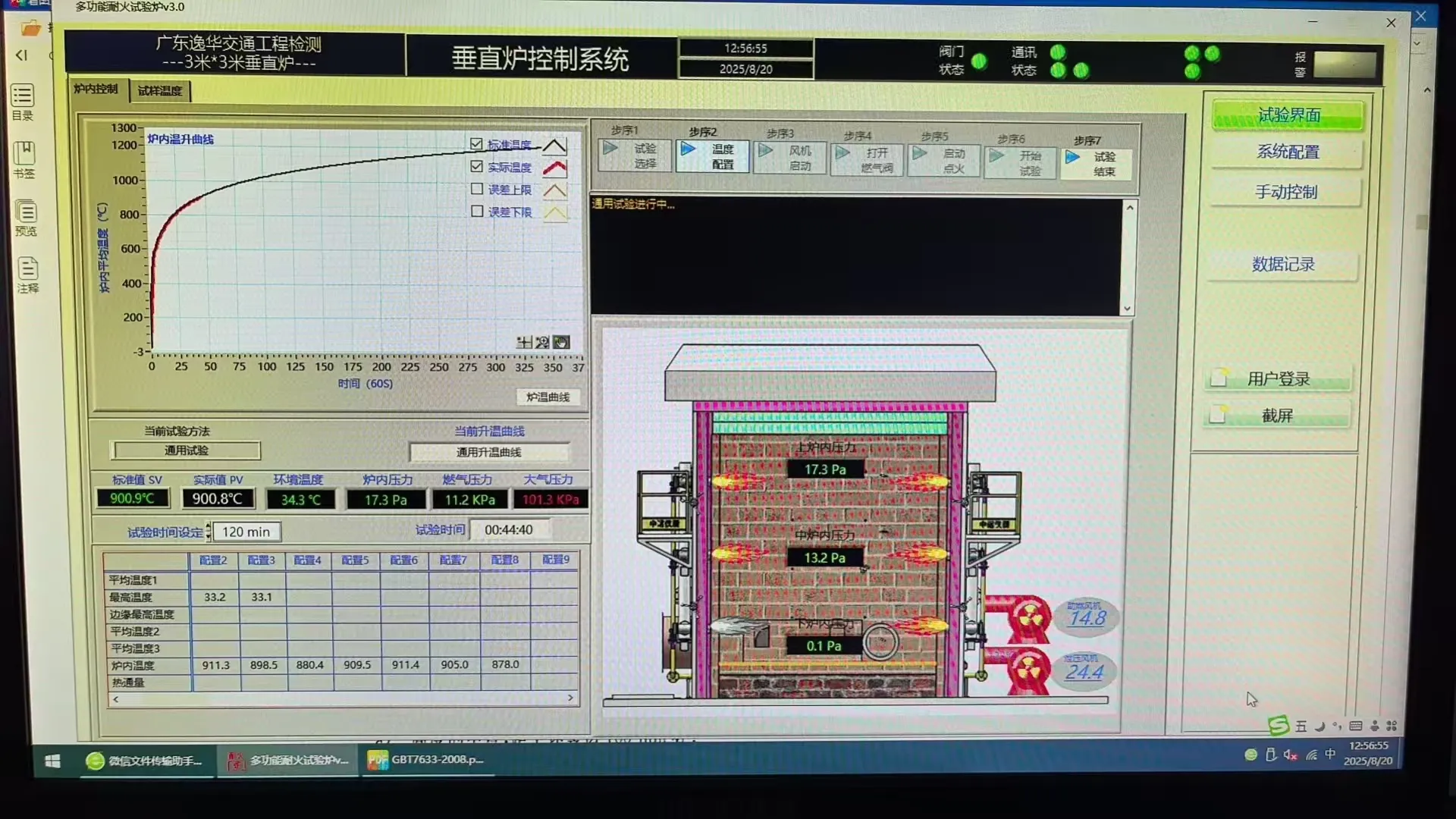

ISO834-1 Standard heating curve-2

ZONSKY vertical combustion furnace supports full-scale fire resistance testing with reliable automation, data precision, and flexible compliance for construction-grade materials.

Scope of Application

Compliant Standards

Performance Characteristics

The furnace uses 16-bit high-precision collection cards to collect data such as temperature, pressure, and flow of various gases. When burning, the real-time information of the fire is generated by the microcomputer analysis, processing, and control system. The result is quickly displayed by the microcomputer. The whole machine uses quality components to ensure that the system is highly advanced.Based on domestic and foreign instruments, our system is continuously optimized with the help of cooperation with research institutes and many companies. After 10 years, it has been continuously improved and proven. Our equipment is now well recognized by many customers and is widely used.

We also use multi-channel modular and microcomputer to implement the PID full automatic control method, which is very reliable.