This NBS Smoke Density Chamber Compliant with BS EN ISO5659-2:2006,ASTM E 662:2006,ISO5659-2:2012 standards,It is suitable for the determination of specific optical density of smoke produced by solid materials or assemblies in flameless mode or flame mode.

The chamber measures smoke by tracking how much light is obscured by smoke particles over time, giving a quantitative assessment of smoke density. This test is widely used in fire safety regulations and standards to ensure materials meet specific safety requirements.

Compliance:BS EN ISO5659-2:2006 "Plastic—Smoke Generation—Part 2: Determination of optical density by a single-chamber test";ASTM E 662:2006 "Standard test method for specific optical density of smoke generated by solid materials".

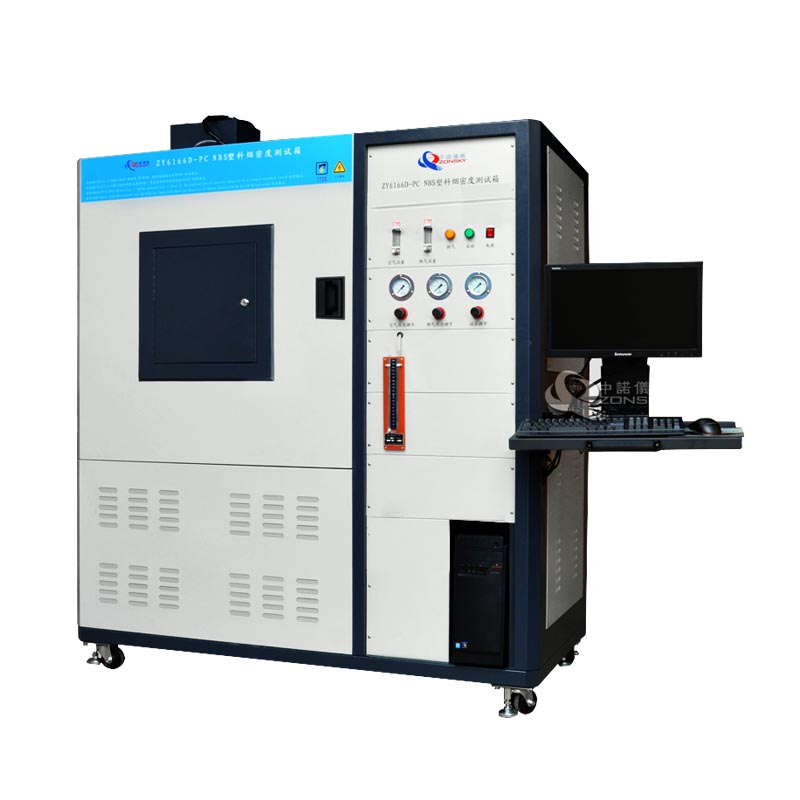

1 The complete set of equipment includes a set of test devices, test boxes, smoke density measurement devices, data acquisition systems and control boxes in accordance with GB/T8323-2008 and ASTM E662.

2 Smoke density test box: It consists of closed combustion test box, photometer measurement system, radiation cone device, combustion system, weighing instrument, igniter, test box, bracket, temperature measuring instrument and smoke density test software.

2.1 The internal dimensions of the test chamber: length 914±3(mm), height 914±3(mm), depth 610±3(mm), the inner and outer walls are made of metal layers that are resistant to chemical corrosion and easy to clean;

2.2 The hinged front door of the test chamber is designed to be fully open, the front door is equipped with a viewing window, and a movable opaque shading plate is installed in front of the viewing window.

2.3 Outer box specifications: The outer box is an integrated design for the convenience of operation. Dimensions: length 1822(mm), width 860(mm), height 1970(mm).

3 Radiation cone device

3.1 The radiation cone device includes electric heating tube, weighing unit, PID temperature controller, heat flow meter, sample box, ignition, and conforms to GB/T8323.1, GB/T8323.2, ISO5659-2:2012 and other standards Regulation.

3.2 The rated power of the electric heating tube is 2600W. It is installed in a double-layer stainless steel shell and filled with heat-resistant fiber cotton. It can provide 10KW/m²~50KW/m² radiation intensity in the center of the sample surface. When testing the irradiance of the other two positions 25mm away from the center of the sample, the irradiance of these two positions cannot be lower than 85% of the irradiance of the center of the sample, and the control accuracy is ±0.5 kw/m².

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now