It is suitable for fire emergency lighting and evacuation indication systems installed in general industrial and civil buildings, as well as system lights with special performance installed in other environments.

ZONSKY Fire Emergency Lighting & Evacuation Indication System Testing Apparatus is designed to assess the functionality, brightness, and reliability of emergency lighting and evacuation indicators under simulated fire conditions. This apparatus tests parameters such as luminance, battery backup duration, visibility in smoke-filled environments, and directional accuracy of exit signs.It is suitable for fire emergency lighting and evacuation indication systems installed in general industrial and civil buildings, as well as system lights with special performance installed in other environments.

Compliance:ISO 30061:2007;EN 1838;IEC 60598-2-22;NFPA 101;AS 2293.1:Emergency escape lighting and exit signs for buildings - System design, installation and operation.

Main performance parameters:

Main performance parameters:1. Charge and discharge test

1.1 Battery charging test:

1.1.1 Component surface temperature detection: use wire diameter thermocouple to detect the surface temperature of internal components;

1.1.2 Battery charging current detection: It has the function of continuously detecting overcharging current, and the maximum continuous overcharging current does not exceed 0.05C5A (0.05C20A for lead-acid batteries);

1.3 Battery discharge detection:

1.3.1 Termination voltage detection: with power supply voltage adjustment function, the voltage adjustment range is 50%~150% of the rated voltage;

1.3.2 Discharge current detection: the detection range is 0.01mA~10mA, and the resolution is 0.01mA;

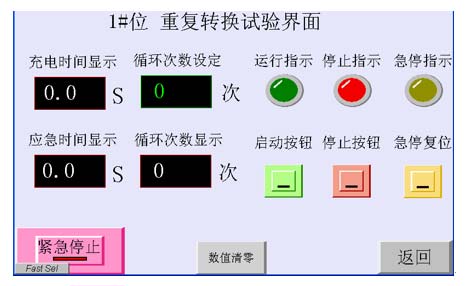

2. Repeat conversion performance detection:

2.1 Main power state time: 0~99min can be set arbitrarily;

2.2 Emergency state time: 0~999s can be set arbitrarily;

2.3 Repeated conversion times: 0~999 times can be set arbitrarily;

3. Voltage fluctuation performance test: use the main power supply test with the power supply voltage adjustment function in section 3.1.3.1, and the voltage adjustment range is 50%~150% of the rated voltage;

4. Conversion voltage performance: Adopt the main power supply detection with the power supply voltage adjustment function in section 3.1.3.1, and the voltage adjustment range is 50%~150% of the rated voltage;

5. Charge and discharge durability:

5.1 Charge and discharge endurance times: 0~999 times can be set arbitrarily;

5.2 Full charge time record: 0~999h;

5.3 Discharge time record: 0~999min;

6. Insulation resistance test:

6.1 Measurement range: 1kΩ~10TΩ;

6.2 Test voltage: DC500V±50V;

6.3 Voltage measurement accuracy: ±(2%±2Counts) Voltag ≥500VDC

6.4 Resistance measurement accuracy: ±{ 5%±2Counts) Voltage< 500V DC;

6.5 Timing: 60s±5s

7. Withstand voltage performance test:

7.1 Test voltage: AC 0~5kv;

7.2 Leakage current: AC 0~20mA;

7.3 Test time: 1~99s;

7.4 Transformer capacity: 100VA;

7.5 Measurement accuracy: ±3 % (±3 digits);

8. Grounding resistance test:

8.1 Simultaneous display of test time, current and grounding resistance

8.2 Constant current source test current

8.3 Test voltage: 10v;

8.4 Test current: 5~30A

8.5 Test resistance range: 0~600mΩ

8.6 Accuracy: ±5 % (±3 characters)

9. Data acquisition and control: use touch screen + PLC + module acquisition and control.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now