Applicable to ISO 7165:1999 ,ISO 7165:2009,ISO 11601:1999,ISO 11601:2017 standard,for extinguishing Class A, B, and C fire performance test.

ZONSKY Standard Fire Extinguishing Test for Class A Fires apparatus is designed to assess the effectiveness of fire extinguishing agents on Class A fires, which involve combustible materials such as wood, paper, and textiles. This test apparatus evaluates extinguishing performance by measuring factors such as discharge rate, coverage area, and suppression time, ensuring compliance with the GB4066-2017 standard. Fire Extinguishing Performance Test Equipment

ISO 7165:1999 standard fire extinguishing test for class A fire;

ISO 7165:2009 standard fire extinguishing test for class B fire. Excluding 8B, 13B

Applicable to the fire extinguishing tests for Class A and B fires in Sections 7.2 and 7.3 of ISO 11601:1999 "Wheeled fire extinguishers—Performance and Construction", excluding 297B.

1. Test space:

1.1 The height is 7.5m, the volume is 1700m3, and the length and width are greater than 15m*15m;

1.2 The 4 corners of the room have adjustable air intake holes, with a total ventilation area of 4.5m2 or more;

1.3 The ground is a smooth concrete floor;

1.4 Ambient temperature: controlled at 0°C~30°C;

2. GB4066-2017 Standard Class A fire extinguishing test:

2.1 Standard 3kg dry powder fire extinguisher:

2.1.1 Gauge initial pressure: (1.2±0.1) MPa;

2.1.2 Nozzle diameter: Ф4mm;

2.1.3 Inner diameter of nozzle: Ф10mm;

2.1.4 Nozzle length: 400mm;

2.1.5 Cylinder diameter: Ф127.4mm;

2.1.6 The cylinder volume is 3.8L;

2.1.7 The inner diameter of the siphon tube is Ф12mm;

2.1.8 The distance between the siphon and the bottom of the cylinder is 13mm~16mm;

2.2 Wood moisture meter: accuracy ±1%;

2.3 Stopwatch: division value 0.1s;

2.4 Fuel: aliphatic hydrocarbon compound, the distillation range is 84°C~105°C, the temperature difference between initial and final distillation is ≤10°C, the volume content of aromatic hydrocarbon is ≤1%, and the density at 15°C is (700±20) kg/m3.

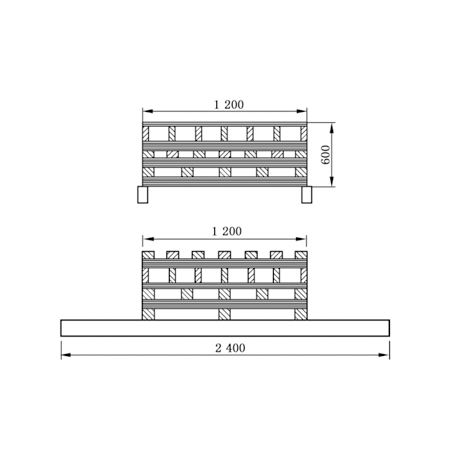

3. Test bracket:

3.1 A total of 7 brackets:

3.1 A total of 7 brackets:

3.2 GB4066 standard 2A is the same as ISO7165 standard 2A, and the level codes are 1A, 2A, 3A, 4A, 6A, and 10A, a total of 6;

3.3 ISO11601 standard: one grade code 15A and 20A;

3.4 Structure: it can support wooden stacks, and the space between them is the size of 8 ignition discs;

3.5 Material: Made of 40mm*40mm stainless steel square tube. The bracket height is 400mm±10mm;

3.6 Wood strips: the buyer should prepare them by himself;

4. Ignition plate:

4.1 There are 8 in total: one for level code 1A, 2A, 3A, 4A, 6A, 10A, 15A, and 20A;

4.2 Material: square, made of stainless steel;

4.3 Fuel: gasoline for automobiles;

5. scales: range 0.1kg~500kg; precision 0.5kg.

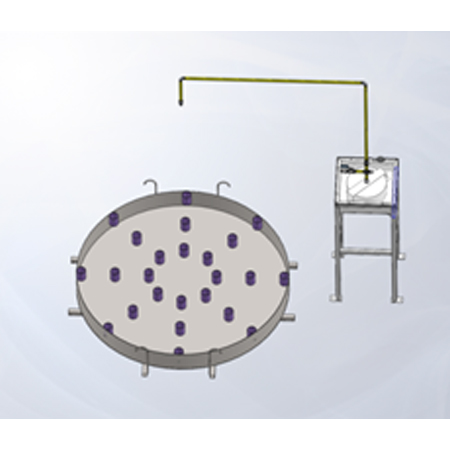

6. GB4066 standard fire extinguishing performance test of Class B and C

6.1 Special 3kg dry powder fire extinguishing device:

6.1.1 One nitrogen charging device; (optional)

6.1.2 Pressure: (1.30±0.05) MPa;

6.1.3 Cylinder specifications: inner diameter about 350mm, volume (12.0±0.2) L;

6.1.4 Nozzle diameter: about Ф9.5mm;

6.1.5 Pipeline: the inner diameter is ≥15mm, the total length (a+b+c)≤4.0m; there are two 90° elbows, and the internal volume of the pipeline is >1.20L;

6.1.6 Tank pressure: ≥2.5MPa, precision ≥0.4;

6.2 Steel oil pan: diameter (1884±20) mm, height (200±15) mm, wall thickness 2.5mm;

6.3 Stopwatch: division value 0.1s; (general purpose)

6.4 Anemometer: accuracy ±0.3m/s;

6.5 Calibration measuring cup: Ф80mm in diameter, 100mm in height, and anti-rebound sponge of dry powder fire extinguishing agent inside, 24 pieces in total;

6.6 Fuel: shared with GB4066 standard for class A fire;

7. Standard ISO 7165, ISO 11601 Class B fire extinguishing test

7.1 Test oil pan: one for fire extinguishing class 8B, 13B, 21B, 34B, 43B, 55B, 70B, 89B, 113B, 144B, 183B, 233B, 297B;

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now