This Hydraulic Pressure Comprehensive Testing Machine is suitable for fire hose test with hose specifications of 25, 40, 50, 65, 80, 100, 125, 150, 200.

ZONSKY Fire Hose Hydraulic Pressure Comprehensive Testing Machine is designed to assess the strength, durability, and leak resistance of fire hoses under high-pressure conditions. This apparatus subjects hoses to controlled hydraulic pressure, measuring parameters such as burst pressure, pressure loss, and structural integrity over time.

Compliance:ISO 6182-6;EN 14540;NFPA 1961;BS 6391;JIS K 2331;AS 2792;

1. It is suitable for fire hose test with hose specifications of 25, 40, 50, 65, 80, 100, 125, 150, 200. Among them, the hose specifications 50 and 65 are standard configuration, and our company will provide corresponding accessories at random. If you need to test other specifications of hoses, you need to purchase additional accessories of corresponding specifications with our company.

1. It is suitable for fire hose test with hose specifications of 25, 40, 50, 65, 80, 100, 125, 150, 200. Among them, the hose specifications 50 and 65 are standard configuration, and our company will provide corresponding accessories at random. If you need to test other specifications of hoses, you need to purchase additional accessories of corresponding specifications with our company.

2. Applicable to working pressure, test pressure and minimum burst pressure in Table 1. Unit: MPa

Working pressure | Test pressure | Minimum burst pressure |

0.8 | 1.2 | 2.4 |

1.0 | 1.5 | 3.0 |

1.3 | 2.0 | 3.9 |

1.6 | 2.4 | 4.8 |

2.0 | 3.0 | 6.0 |

2.5 | 3.8 | 7.5 |

3. It is suitable for the water seepage test of the wet water belt as a pressure source, the device is optional, and the cost is extra;

3. It is suitable for the water seepage test of the wet water belt as a pressure source, the device is optional, and the cost is extra;

4. It is suitable for elongation and expansion and torsion test as pressure source. Equipment optional, the cost is extra;

5. It is suitable for hose bendability test as pressure source. Equipment optional, the cost is extra;

6. It is suitable for the wear resistance test of the hose as a pressure source. Equipment optional, the cost is extra;

7. It is suitable for the performance test of the connection between the hose and the fire coupling;

8. It is widely used in the production inspection and development research of various fire hoses by production factories, product quality inspection institutes, scientific research institutions and other units.

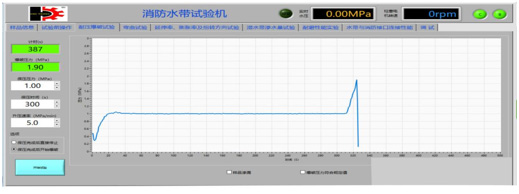

1. The computer + PLC + module collects data and controls the pressure, flow, pressure holding time and pressure increase rate, etc.

2. Adopt the automatic clamping and sealing technology of the hose, which solves the time-consuming and laborious problem of clamping and sealing the hose of the old testing machine. The test is automatically controlled by the computer, and the test data is recorded in the whole process, and the report can be automatically generated according to the requirements, so that the hose test can be realized efficiently and automatically. Small footprint, compact structure, high degree of automation, water recycling, stable work and complete accessories.

3. Safety measures:

3.1 The high-pressure system adopts double insurance precautions, that is, the pressure transmitter controls the water pressure, and the electric contact pressure gauge controls the maximum water pressure. On the one hand, if it fails, on the other hand, it can also ensure the safety of test personnel and equipment.

3.2 There may be water leakage during the test, and the two ends of the water belt in the water-bearing part are fully sealed and waterproof with fastening devices. Plus 24V low voltage control, plus time relay control, three-layer protection of waterproof, anti-electricity and anti-failure.

4. The pressurization system is composed of an imported liquid booster pump, a pressure regulating part of a frequency converter, etc. It mainly completes the pressurization and pressure maintenance of the system, which can ensure the pressurization and pressure maintenance of the long-term test.

5. The test process is controlled by a microcomputer, the test pressure time curve is displayed in real time, the test results can be automatically saved, or printed out, and the power can be automatically saved;

6. our company independently completed the second development. The coupling is rigorous, clear and easy to control;

7. The fixture and tooling configuration is complete, and the installation is convenient and fast;

8. The overall design is reasonable and the maintenance is convenient. Automatic constant pressure, slight leakage automatically replenishes constant pressure. The high-pressure pipeline is made several times and is durable.

1. Instrument composition: it consists of pressure source, test part and operation control part;

2. Source of stress:

2.1 Test medium: water (recycling, with filter device);

2.2 Pressure range: 0.05Mpa~10MPa;

2.3 High pressure pump pressure: 0~15Mpa;

2.4 Boost rate: 5~15Mpa/min;

2.5 Voltage stabilization device: when the water pressure is less than 3.0MPa, the pressure fluctuation value is less than ±0.05MPa; when the water pressure is higher than 3.0MPa, the pressure fluctuation value is less than ±0.1MPa;

2.6 Pressure sensor: 0~15Mpa. The accuracy is ±0.01MPa, and the resolution is 0.001MPa;

2.7 Pressure collection interval: 100ms;

2.8 Flow rate: 16L/min.

3. Test part:

3.1 Sample length: 1.2m;

3.2 A set of sealing device with exhaust valve;

3.3 Measurement of water seepage in wet water belt:

3.3.1 Water collection tank: made of stainless steel, the size is (1000±5) mm long, and the width and depth are 100 mm;

4. Operation control part:

4.1 Use computer + PLC + module to collect and control;

4.2 The pressure control and voltage stabilization are controlled by frequency converter;

4.3 Pressure holding time: 0~99.99min can be set;

5. Power of the whole machine: 10KW

6. Dimensions:

6.1 Host volume (approx.) length 3.4m × width 0.85m × height 1.65m

6.2 Weight of the whole machine: 750kg.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now