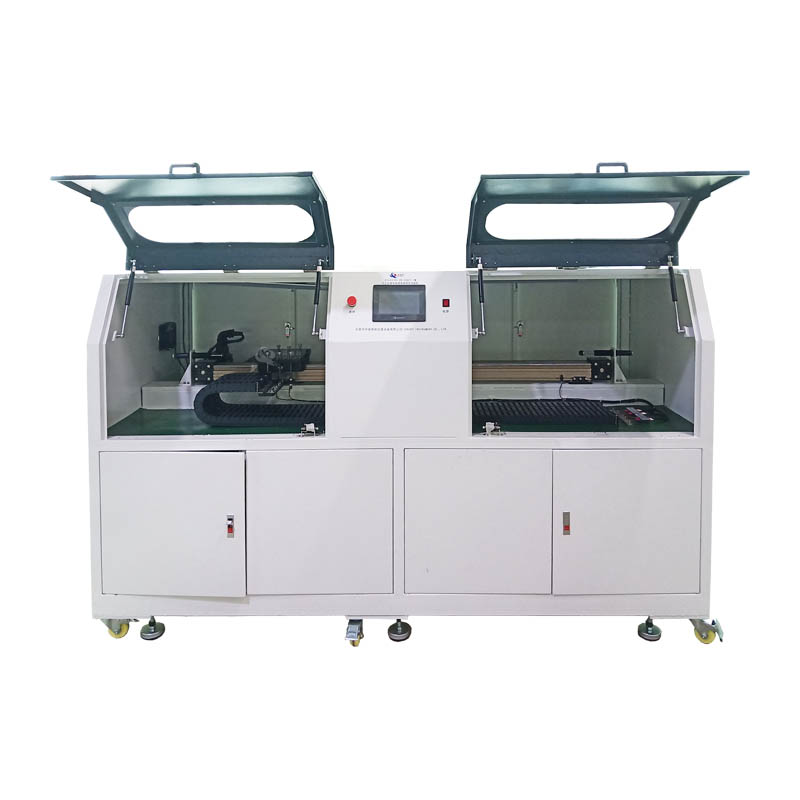

this machine is a four -site design of the front and rear,Suitable for high-flexible cables such as TUV, VDE, UL, repeated U-shaped bending fatigue tests, and need to be curved in high-speed exercise.

ZONSKY for high-flexible cables such as TUV, VDE, UL, repeated U-shaped bending fatigue tests, and need to be curved in high-speed exercise. Such as the repeated bending fatigue test of the internal display of the machine, the high-speed dragging system cable, the connected cable of the machine activity component, the internal wiring of the machine, and the industrial dragging cable, and the industrial robot cable.

The function of this machine is a four -site design of the front and rear, with independent test parameters setting and the identification of test data collection and test results. Improving test efficiency and reducing energy for enterprises.

It is mainly used to detect whether the flexible wires and cables are driven by the dragging chain. After repeated high-speed U-shaped bending tests, whether the short-circuit, the insulation sheath is cracking, damaged or other abnormal phenomena. It detects the performance of plastic deformation in the repeated high-speed U-shaped bending test and the shortcomings that are highlighted.

compliance: TUV 2PFG2577-08.16, DIN VDE 0295, and the standard CRIA 0003.2-2016 "Special cables for Industrial robots Part 2: Test Method" for the Standard CRIA 0003.2-2016.

1.Design is novel: Design is a two -station two -track operation before and after, with independent test parameters settings and test data collection and test results. Improving test efficiency and reducing energy for enterprises.

2. Collection data: use PLC to capture data and collect data;

3. Control and Settings: Microscopic control and touch -touch LCD screen, menu -type design: test speed, number of tests, test procedures, locks of test results, and other functions;

4. Monitoring and real -time data shows that the four groups of monitoring methods are used to monitor the circuit of each group of samples, and automatically determine the interruption of each group of samples, detect the automatic shutdown when the circuit is disconnected, and the real -time operation state can be retrieved at any time. For example, real -time speed, number of operations, exercise itinerary, etc.;

4.1 Testing station: It is a two -track front and rear track, a total of 4 test samples;

4.2 Test method: horizontal bending, the sample is fixed in the corresponding dragging chain, followed by the dragging chain as a horizontal direction bending test;

4.3 Power off signal voltage: DC24V

4.4 Test space: each station can install the width of the drag chain 40mm-125mm;

4.5 Total number of dragging chain cables: multi core, the connection of the interrupt circuit is the way of series circuit;

4.6 Running itinerary: 1000mm;

4.7 Test speed: 60 times/minute.

4.8 Bending radius: Fixed height 30mm-150mm adjustment up and down, suitable for dragging chains with a curved radius of 15mm-75mm (according to the diameter of the sample with a suitable drag chain, this machine contains only one.)

4.9 counting digits: 0-99999999 settings at any setting;

4.10 Madam: Using servo motors

4.11 The size of the whole machine: 1600mm*width 950mm*height 1750mm

4.12 Power: AC220V, 50Hz 3500VA

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now