The Combustion Tester Comply with the standard requirements of IEC60331,It is suitable for testing whether the wire or optical cable maintains the circuit integrity during the fire supply under the flame of at least 750℃ and 830℃.

The Circuit Integrity Under Fire Conditions Apparatus is a specialized testing device designed to evaluate the operational resilience of electrical circuits when exposed to fire. This apparatus subjects cables and wiring systems to high-temperature flame exposure, monitoring parameters such as conductor continuity, insulation integrity, and circuit functionality throughout the test. It provides essential data on the fire-resistance performance of electrical components。

1. IEC60331-11:1999 "Test for electric cables under fire conditions - Circuit integrity - Part 11: Apparatus - Fire alone at a flame temperature of at least 750°C";

2. IEC60331-12:2002 "Test for electric cables under fire conditions - Circuit integrity - Part 12: Apparatus - Fire with shock at a temperature of at least 830℃";

3. IEC60331-21:1999 “Test for electric cables under fire conditions - Circuit integrity - Part 21: Procedures and requirements - Cables of rated voltage up to and including 0.6/1.0kv”;

4. IEC60331-23:1999 “Test for electric cables under fire conditions - Circuit integrity - Part 23: Procedures and requirements - Electric data cables”;

5. IEC60331-25:1999”Test for electric cables under fire conditions - Circuit integrity - Part 25: Procedures and requirements - Optical fibre cables”;

6. IEC60331-31:2002“Test for electric cables under fire conditions - Circuit integrity - Part 31: Procedures and requirements for fire with shock - Cables of rated voltages up to and including 0.6/1.0kv ”;

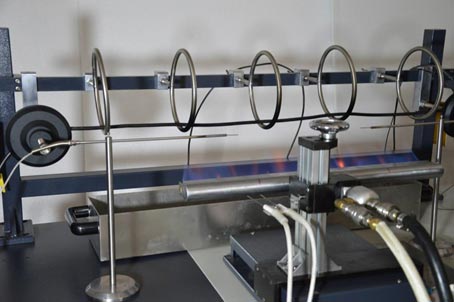

1. GB/T19216.11-2003 standard test support device: the sample holder has a total of 3 support rings, the inner diameter of the metal ring is about 150 mm, and it is made of round steel rods with a diameter of (10±2) mm. During the test, the sample is placed on the support ring, one end of the sample is fixedly clamped to prevent movement, and the other end is supported to allow the sample to move longitudinally due to thermal expansion. Comply with GB/T19216.11-2003, GB/T19216.21-2003, GB/T19216.23-2003, GB/T19216.25-2003 standards, see Image 2 below

2. GB/T19216.12-2008 test ladder frame: composed of steel frame, suitable for the test of cables of different sizes, the two central vertical members on the test ladder frame can be adjusted. The test ladder is 1200mm long and 600mm high, and the total mass of the test ladder is (18 ± 1) kg. Adapt to GB/T19216.12-2008, GB/T19216.31-2008 standards;

3.GB/T19216.12 Impact generating device: The impact generating device consists of a low carbon steel round bar with a diameter of (25±0.1MM) and a length of (600±5MM), which is wound around a The axis of the test ladder is free to rotate, and it is located in the same horizontal plane (200±5MM) from the upper edge of the test ladder. This axis divides the round bar into two unequal lengths, namely (400±5MM) and approximately 200MM, respectively, and the longer part strikes the test ladder frame. The round bar is dropped by its own weight from an angle of 60°C with the horizontal plane, and is struck once at the midpoint of the test ladder every 30 s ± 2 s. Comply with GB/T19216.12-2008, GB/T19216.31-2008 standards;

4. Burner: A belt-type propane gas burner with a venturi mixer with a nominal length of 500mm of the fire surface. The nominal width of the fire surface is 15mm, and there are three rows of staggered drill holes with a nominal diameter of 1.32mm and a center-to-center distance of 3.2mm.

5. Gas control system: It consists of regulating valve, high pressure automatic igniter, flameout device, control thermocouple, propane gas cylinder, screw valve, pressure gauge, flow meter, venturi mixer, blowtorch, ball valve, compressed air tank, etc.

6. GB/T19216.11-2003 Standard Blowtorch System Verification:

6.1 Measuring temperature: use two K-type thermocouples (in line with GB/T16839.1 standard) with Φ1.5mm mineral insulated stainless steel sheath;

6.2 Flame temperature: adjustable from 750° to 1000°.

6.3 Combustion gas: propane with a purity of 98%.

6.4 Combustion-supporting gas: compressed air. (The air pressure needs to reach more than 10Mba);

6.5 Flowmeter: Two rotor flowmeters are used. Air flow: 0~200L/min, propane (gas) flow: 0~20L/min. Adjustable flow;

6.6 Thermocouple installation position: place the torch at a distance of about 45mm (x mm) horizontally from the thermocouple and 70 mm (y mm) vertically downward from the centerline of the thermocouple;

.6.7 Verification Judgment: The average value of the readings of the two thermocouples within 10 minutes is within the required range of (750±050) °C, and the maximum difference between the average readings of the two thermocouples does not exceed 40 °C, it shall be considered as passed. verify. In order to obtain the average value, it should be measured at least once every 30s;

6.8 Verification timer: 0~99.99min can be set arbitrarily, it will stop automatically when it reaches the set value, accuracy: ±1s/h.

7. GB/T19216.12-2008 Verification of heat source

7.1 Measuring temperature: use two K-type thermocouples (in line with GB/T16839.1 standard) with Φ1.5mm mineral insulated stainless steel sheath;

7.2 Flame temperature: adjustable from 750° to 1000°.

7.3 Combustion gas: propane with a purity of 98%.

7.4 Combustion-supporting gas: compressed air. (The air pressure needs to reach more than 10Mba);

7.5 Flowmeter: Two rotor flowmeters are used. Air flow: 0~200L/min, propane (gas) flow: 0~20L/min. Adjustable flow;

7.6 Installation position of thermocouple and blowtorch: The temperature measuring head of thermocouple is located at (20±1) mm in front of the test wall. The horizontal line of the thermocouple is located approximately 100 mm above the bottom of the test wall. The test wall is composed of a non-combustible non-metallic material heat-resistant plate with a length of 900mm, a height of 300mm and a thickness of 9mm; the torch is placed at a horizontal distance of 100mm~120mm from the thermocouple, and the vertical downward distance from the thermocouple center line is 40mm~60mm position.

7.7 Verification Judgment: If the average reading of the two thermocouples within 10 min is within the required range of (830±040) °C, and the maximum difference between the average readings of the two thermocouples does not exceed 40 °C, it shall be considered as passed. verify. In order to obtain the average value, it should be measured at least once every 30s;

7.8 Verification timer: 0~99.99min can be set arbitrarily, it will stop automatically when it reaches the set value, accuracy: ±1s/h.

8. Ignition device: use Changming small flame to ignite.

9. Fire time: 0--999min

10. Power requirements: AC380 (±10%) V/50HZ.

11. Machine operating power: 1KW.

12. Continuity checking device:

12.1 GB/T19216.21, GB/T19216.23, GB/T19216.31 standard continuity inspection device:

12.1.1 During the test, the current used for continuity check is passed through all conductors of the cable. The current is supplied by a three-phase star-connected transformer with sufficient capacity to maintain the required leakage current even when the maximum allowable leakage current is reached. Test voltage. At the other end of the test piece, each conductor or group of conductors is connected to a suitable load and indicating device (eg a light bulb) to form a current (with a ballast resistor if necessary). Under the test voltage, the current through each conductor or group of conductors is 0.25A.

12.1.2 Fuse: It is a 2A fuse, which conforms to the DII type specified in GB13539.5.

12.1.3 Test voltage (phase voltage): 0--1000V continuously adjustable.

12.2 GB/T19216.25 Standard Continuity Check Device: It only provides on-off test of optical fiber, and does not provide measurement of changes in optical transmission. If the optical instrument is used for continuity inspection, the optical instrument should be provided by the customer, and the connection method should be monitored and measured according to C10 specified in GB/T15972.4 for changes in optical transmission.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now